Hera, a few general recommendations regarding material models for implicit analyses in LS-DYNA are presented. For a detailed description of the material models available in LS‑DYNA, see Keyword Manual Vol II. Presently, most but not all material models are supported for implicit analysis. If unsupported materials are used, LS-DYNA will print an error message in the d3hsp file and terminate.

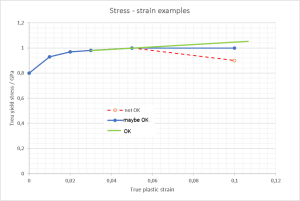

The material model *MAT_PIECEWISE_LINEAR_PLASTICITY (or MAT_24) is commonly used in explicit LS-DYNA analyses to characterize metallic materials with plasticity, and it performs well also for implicit analyses. To reduce the risk for convergence issues, it is recommended to avoid a negative slope of the last segment of the hardening curve

An alternative to *MAT_24, if anisotropy or kinematic hardening is of interest, may be *MAT_103. A template for basic use of MAT_103, with isotropic hardening and no strain rate effects, follows:

*MAT_ANISOTROPIC_VISCOPLASTIC_TITLE Define material title MID, RO, E, PR, 0., 2, LCSS, 1. Blank line x 5

The parameter LCSS is the load curve ID of the hardening curve. After the line defining material ID, density etc., five blank rows must follow. For mixed or kinematic hardening with a non-linear hardening curve, *MAT_225 could be of interest. The *MAT_DAMAGE_3 (MAT_153) is a Chaboche-type material model for nonlinear mixed or kinematic hardening, including a possibility to specify temperature dependent material parameters.

If a material model with linear isotropic hardening using a tangent modulus is required, it is recommended to use *MAT_24. Then, only specify the yield stress (SIGY) and the tangent modulus (ETAN) on card 1 (and of course also the elastic parameters) and leave the other cards blank. It is not recommended to use *MAT_PLASTIC_KINEMATIC (*MAT_3 with the parameter BETA = 1 if isotropic hardening is desired; instead use *MAT_24.

For linear implicit analyses (nsolvr=1 or -1 on *CONTROL_IMPLICIT_SOLUTION), the material response is linearized, but stresses will be computed from the strains obtained via the displacement solution to the linear problem. Since no equilibrium iterations are performed in a linear analysis, the obtained stresses can be nonsensical. If consistent estimates of stresses are of interest in a linear analysis, it is recommended to use *MAT_ELASTIC, which is an elastic material model. From R15 of LS-DYNA, material models and stress computations are automatically linearized in linear analyses.

It is not recommended to use *MAT_ELASTIC to model rubber-like behavior in a non-linear analysis, since it is a hypoelastic material model, which may cause instabilities at large strains. For modelling of rubber materials, it is instead recommended to use *MAT_HYPERELASTIC_RUBBER (MAT_77). An alternative material model for rubber materials is *MAT_SIMPLIFIED_RUBBER_FOAM (MAT_181), which allows for direct input of results from materials testing. The material model *MAT_MOONEY-RIVLIN_RUBBER (MAT_27) is in general not recommended for modelling of rubber or rubber-like materials, see Appendix A for further details. If an elastic response is desired, *MAT_ORTHOTROPIC_ELASTIC (MAT_2) can be used, since it is a hyperelastic material model which works also for large elastic deformations.

For modelling of creep effects, LS-DYNA offers many possibilities; for example, *MAT_THERMO_ELASTO_VISCOPLASTIC_CREEP (MAT_188) may be useful.